98%

Service and Maintenance contacts to be added

120

UK quarry sites have our equipments

92%

Re-order rate from our previous client

80%

Average reduction in airborne dust using foam systems

Our Solutions

Designed to deliver effective dust control tailored to the unique challenges of each site. By combining innovative technology with practical, cost-efficient design, we help protect people, processes and the environment.

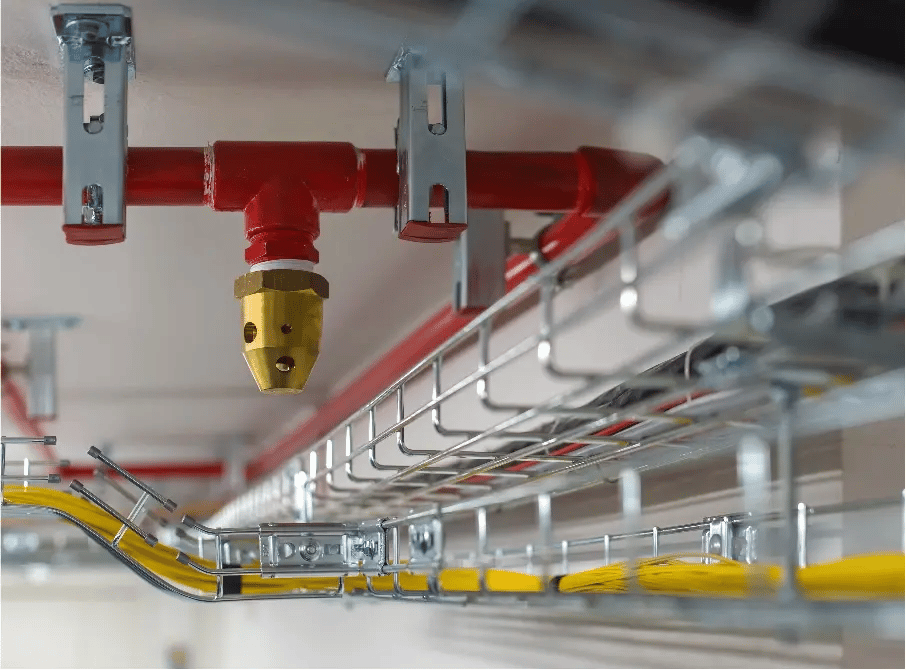

Foam Systems

Misting Systems

Sprinkler Systems

Rail Wagon Encapsulation

Stock Pile Encapsulation

Foam Dust Suppression Measures

Crete Away+

Request A Callback

Trusted By Industry Leaders

Our Process

At Best-Chem, we recognise that every site and operation is unique. Our process has been carefully developed to provide clarity, confidence and exceptional results at every stage.

Initial Enquiry

We gather information about your processes, challenges and current control measures through enquiry questionnaires, online meetings or a site survey. This ensures that we have a clear picture of your requirements.

Design

Each design is created with a clear focus on achieving effective dust control while balancing specific complexities of your site. Our proposals set out the recommended equipment, estimated consumption, upfront investment and projected running costs.

Field Trials and Demonstration

Our team can rapidly & safely install demonstration equipment with minimal disruption. The effectiveness of our foam systems is visible almost immediately, and we can extend the trial to cover a variety of scenarios to provide robust on-site evidence for a permanent solution.

Build

Every unit undergoes thorough factory acceptance testing. Wherever possible, we complete pump set assembly and plant room configuration off-site, helping us to deliver an efficient installation with minimal downtime.

Installation

Our installation engineers bring experience & a collaborative approach to the project. Safety and efficiency are at the heart of our work, and we ensure that each installation is carefully planned, clearly communicated and expertly executed in partnership with your site team.

Commissioning

We dedicate the time needed to observe the system in operation, monitor performance & ensure seamless integration with your process. Training and familiarisation are provided so that your staff are confident in operating the system.

Service and Maintenance

Best-Chem provides dedicated service and maintenance support to keep your equipment fully operational and compliant. With regular attention, your system will continue to protect your people, processes and reputation.

Sectors

We work across a wide range of industries, from mining and quarrying to power, recycling, steel and beyond. Wherever dust control is critical, our expertise and tailored solutions keep operations safe, efficient and compliant.

Mining

Asphalt Plants

Concrete Plants

Quarrying

Power Stations

Bulk Port Terminals

Recycling Industries

Rail Operation

Steel Plants

Download Your Free Dust Suppression Guide

Looking to improve efficiency, stay compliant, and reduce environmental impact? Our FREE Dust Suppression Guide is designed to help you choose the right solution for your site, no matter the size or sector.

This practical guide covers:

Key challenges and how to overcome them

Recommended systems and technologies

Cost-saving tips and maintenance best practices

Compliance insights and environmental benefits

Whether you're just starting out or looking to optimise your existing setup, this guide is packed with expert advice to support your operations and long-term growth.

Simply fill out the form to get instant access.

Specialists In Foam Suppression Solutions

A highly effective solution to suppress airborne dust in bulk mineral handling using minimal moisture and outperforming traditional methods.

Targeted Dust Suppression: Foam dampens fine particles at the source, reducing airborne dust before it becomes a problem.

Minimal Moisture Added: Uses up to 70% less moisture than traditional water sprays, preserving material integrity and minimizing process disruption.

Proven Effectiveness: Delivers results that frequently surpass those achievable with conventional wet suppression systems.

Frequently Asked Questions

Depending on the nature of the dust problem, we typically require:

- Description of the issue

- Layout drawings / Process flow sheet

- Photos / videos

- Do you have your own installation team?

Based on this initial information we can begin outlining a solution.

This will then lead to further detailed information gathering and possibly a site survey.

Our standard foaming agents suppress dust by efficiently dampening the dust particles, using only minimal moisture. They do not contain any additional binders or ‘tackifiers’. In situations where you want to separate the dust, and avoid dust sticking to larger material, this would be the recommended product.

For instances where additional binding of dust particles is advantageous, we have foaming agents with binders. These also provide extended dust control, trapping dust after the material has dried out.

The chemical is manufactured in-house our own facility in the UK.

Why Our Clients Choose BestChem

Our Director is massively impressed with your crete away.Please could you send over a pro forma for a pallet